In the realm of furniture manufacturing, the Plastic Rattan Stool Mold stands as a quintessential innovation, in both the aesthetics and functionality of seating solutions. With its versatile design and performance, this mold has become an indispensable tool for crafting durable and stylish rattan stools. Let's delve into the intricate details of how this mold has evolved, enhancing the performance of rattan stools across the globe.

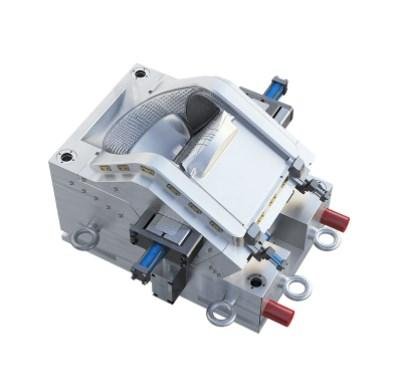

The Plastic Rattan Stool Mold represents advancements in materials engineering and mold design. Conceived as a solution to the limitations of traditional rattan furniture production, this mold has undergone significant transformations to meet the evolving demands of the market.

One of the key features of the Plastic Rattan Stool Mold is its adaptability to various shapes and sizes. Unlike conventional molds, which often restrict design possibilities, this innovative mold allows for intricate detailing and customization. Whether it's a sleek contemporary design or a rustic charm, the Plastic Rattan Stool Mold can accommodate diverse aesthetic preferences with ease.

Moreover, the mold's compatibility with plastic rattan material offers unparalleled durability and weather resistance. This unique combination ensures that rattan stools crafted using this mold can withstand the rigors of outdoor use, making them ideal for patio settings, gardens, and poolside lounges. The inherent strength of the plastic rattan also reduces maintenance requirements, further enhancing the practicality of these stools.

Furthermore, the Plastic Rattan Stool Mold incorporates advanced molding techniques to optimize production efficiency. Its streamlined workflow enables manufacturers to mass-produce rattan stools without compromising on quality or precision. This efficiency not only reduces production costs but also allows for swift fulfillment of customer orders, thereby bolstering overall market competitiveness.

As sustainability becomes a concern in the furniture industry, the Plastic Rattan Stool Mold shines as an eco-friendly alternative to traditional manufacturing methods. By utilizing recycled materials in the production of plastic rattan, this mold reduces environmental impact without sacrificing performance or aesthetics. Additionally, its longevity ensures a prolonged product lifespan, reducing the need for frequent replacements and reducing waste generation.

The versatility of the Plastic Rattan Stool Mold extends beyond its primary function, as it catalyzes design innovation. Designers and artisans worldwide are leveraging the capabilities of this mold to push the boundaries of creativity and craftsmanship. From intricate weaving patterns to unconventional shapes, the possibilities are limitless, allowing for the creation of truly unique and captivating rattan stools.

Furthermore, the Plastic Rattan Stool Mold has democratized access to high-quality furniture, making it accessible to a broader demographic. Its cost-effectiveness and scalability have empowered small-scale manufacturers and artisans to enter the market, fostering entrepreneurship and economic growth in various regions. This democratization of production not only promotes diversity in design but also enriches cultural heritage through the preservation of traditional craftsmanship.

In conclusion, the Plastic Rattan Stool Mold stands as a testament to the transformative power of innovation in the furniture industry. Its unparalleled performance, versatility, and sustainability have redefined the standards of rattan furniture production, setting a new benchmark. As technology continues to evolve, we can expect further enhancements and refinements in mold design, paving the way for even greater achievements in the realm of furniture manufacturing.